Content

Material Science in Frame and Component Design

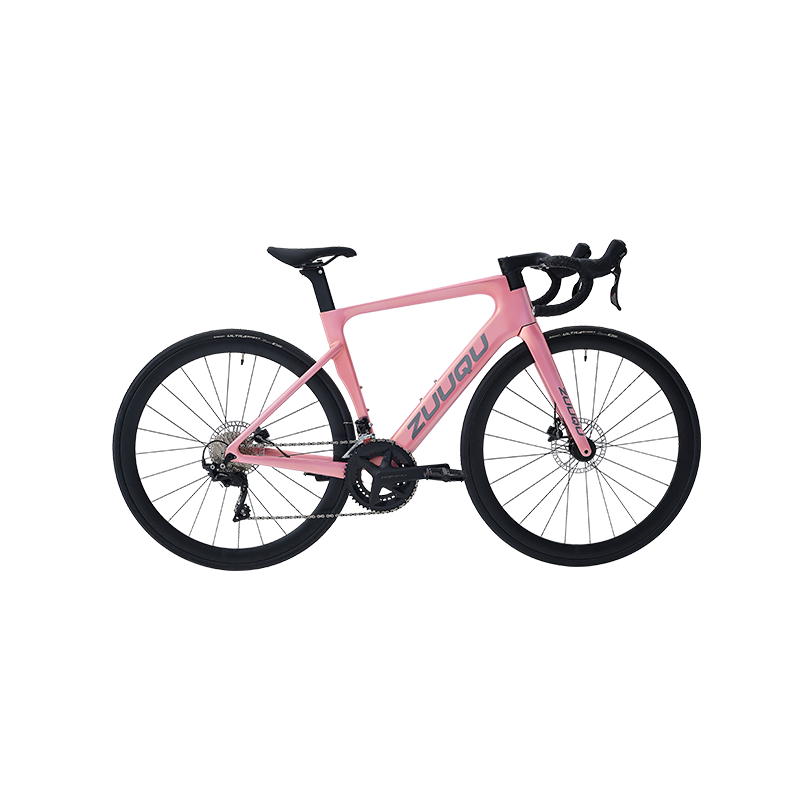

1. Carbon Fiber Dominance

Carbon fiber composites remain the gold standard for high-end road bike frames due to their unmatched strength-to-weight ratio (up to 1,200 MPa tensile strength at 1.3 kg/m²). Innovations include:

-

Layup Optimization: AI-driven algorithms design layer orientations to balance stiffness, compliance, and weight.

-

Hybrid Construction: Combining high-modulus (HM) and intermediate-modulus (IM) fibers for targeted performance (e.g., HM in bottom brackets for power transfer, IM in seat stays for vibration damping).

2. Alternative Materials

-

Titanium Alloys: Resurging in custom builds for durability and ride quality (e.g., 3Al/2.5V titanium with 6-4 ELI grades).

-

Sustainable Composites: Flax fiber-reinforced epoxy (30% lighter than carbon) and recycled carbon fiber from aerospace waste.

-

Additive Manufacturing: 3D-printed titanium lugs paired with carbon tubes for bespoke geometries.

3. Component Advancements

-

Ceramic Bearings: Reduced friction (0.1% vs. 0.3% in steel) in hubs and bottom brackets.

-

Graphene-Enhanced Tires: 18% lower rolling resistance and 50% higher puncture resistance (Vittoria’s 2024 lab data).

Aerodynamics: From Wind Tunnels to Real-World Efficiency

1. Computational Fluid Dynamics (CFD)

CFD software (e.g., ANSYS Fluent) simulates airflow at 40–60 km/h, optimizing:

-

Tube Shapes: Truncated airfoils (Kammtail profiles) reduce drag without UCI rule violations.

-

Fork and Handlebar Integration: Hidden cables and internal routing cut drag by 8–12%.

2. Component-Specific Innovations

-

Wheelsets:

-

Disc vs. Rim Brakes: Disc systems add 150–300g but improve aerodynamic efficiency by 3–5% at 40 km/h.

-

Hollow-Core Rims: 25mm–35mm depths balance crosswind stability and drag (Savings: ~15W at 45 km/h).

-

-

Aero Saddles: Narrow profiles with cutouts (e.g., Specialized Power Mimic) reduce turbulence around the rider’s legs.

3. Rider-Bike Interaction

-

Position Optimization: A 10° drop in torso angle saves 20W at 40 km/h but requires rigorous flexibility training.

-

Skin Suits and Helmets: Dimpled textures and tail spoilers contribute 30% of total aero gains.

Electronics and Data-Driven Performance

1. Integrated Sensor Ecosystems

-

Power Meters: Strain-gauge pedals (e.g., Favero Assioma) and spider-based systems (Quarq DZero) offer +/- 1% accuracy.

-

Electronic Groupsets: SRAM Red AXS and Shimano Dura-Ace Di2 enable micro-adjustments via Bluetooth/ANT+.

2. AI Coaching Platforms

-

Adaptive Training: Platforms like TrainerRoad use machine learning to adjust workouts based on power, heart rate, and fatigue metrics.

-

Race Simulation: Virtual elevation maps paired with smart trainers replicate Grand Tour climbs (e.g., Alpe d’Huez gradients).

3. Real-Time Aerodynamic Feedback

-

Notio Konect: A handlebar-mounted device measuring CdA (coefficient of drag area) during rides, suggesting positional tweaks.

-

Garmin Rally Sensors: Track pedal stroke efficiency and lateral power loss.

Sustainability Challenges in Road Bike Manufacturing

1. Carbon Footprint Hotspots

-

Frame Production: 60–80 kg CO2 per carbon frame (vs. 20–30 kg for aluminum).

-

Transportation: Asian-made components shipped to EU/US markets add 15% emissions.

2. Circular Economy Initiatives

-

Recycling Programs: Specialized’s “Infinity” program reclaims 95% of carbon from old frames.

-

Bio-Resins: Plant-based epoxies (e.g., GreenPoxy) reduce VOC emissions by 70%.

3. Ethical Material Sourcing

-

Conflict Minerals: Ensuring cobalt-free battery components in electronic groupsets.

-

Fair Labor Practices: Auditing Taiwanese and Cambodian factories for ISO 45001 compliance.

Market Trends and Consumer Demands

1. Gravel-Crossover Bikes

-

All-Road Geometries: Slacker head angles (70°–71°) and 35mm tire clearance dominate 2024 launches.

-

Modular Components: Swappable fork mounts for bikepacking or aero configurations.

2. Customization and Personalization

-

3D Scanned Bike Fits: Retül’s motion capture systems tailor frame geometry to individual biomechanics.

-

On-Demand Paint Schemes: Digital printing allows 24-hour turnaround for custom graphics.

3. Price Segmentation

-

Ultra-Premium ($12,000+): Limited-edition frames with Tour de France tech (e.g., Pinarello Dogma F).

-

Mid-Tier (6,000): Direct-to-consumer brands like Canyon offering pro-level specs.

-

E-Bike Integration: Road e-bikes (e.g., Trek Domane+ LT) target aging enthusiasts with 50Nm torque assist.

Future Technologies in Road Bike Development

1. Smart Materials

-

Shape-Memory Alloys: Self-healing frame resins triggered by UV light or heat.

-

MEMS Gyroscopes: Auto-adjusting suspension in seat posts for variable terrain.

2. Energy Harvesting

-

Kinetic Wheels: Regenerative hubs converting braking energy into assist power (prototype stage).

-

Solar-Powered Sensors: Thin-film PV cells integrated into handlebar tape.

3. Blockchain for Supply Chains

-

Material Provenance: Immutable records for carbon fiber batches and labor practices.

-

Anti-Counterfeiting: NFT-based authentication for high-end components.

Keywords: Road bike engineering, carbon fiber frames, aerodynamic cycling, electronic groupsets, sustainable bike manufacturing, gravel bikes, power meters, CFD optimization, smart materials.

Meta Description: Discover the engineering breakthroughs behind modern road bikes—carbon fiber innovation, aerodynamics, and smart tech. Explore sustainability challenges and future trends in cycling.

0

0

Linhang industry park, Zhuji,

Linhang industry park, Zhuji,  +86-18858280688

+86-18858280688